Before work can start on the installations, the entire work area is carefully checked. This is done by de Vega gas analysts who are notified by fax of where they are to be deployed. For their own protection, all gas analysts carry the X a.m. 5000 equipped with the very latest measurement equipment. The gas analyst then carries out a number of tests on-site. First, the gas analyst conducts an explosive gas and CO2 measurement using the X a.m. 7000 gas detector combined with a floating probe. After a few moments, he has two precise measured values. The display shows immediately that there is no risk of explosion. Here, the readings are documented immediately and later presented to the plant operator. Based on the individual circumstances on-site, another measurement is conducted according to the measurement strategy. This time, the gas analyst uses the Vega ship measurement system CMS. With this instrument, he can conduct substance-specific measurements and is precise. During this measurement, the device flags up a relevant reading at 10 ppm, indicating that the benzene content where this crew is working is too high. The Vega gas analyst cordons off the area and initiates additional steps. Now, further equipment from the Dragger shop comes into play. The high benzene concentration is to be reduced by means of ventilation. This is done using explosion-proof fans, which are installed inside the area where the crew is working. After 24 hours of ventilation, the gas analyst begins his measurement cycle again. Now that the readings are okay, the gas analyst documents his measurement results and passes them on to the operator. He then gives the green light for the crew to begin work again. Firstly, a continuous gas detection system is installed in the area where the work is to take place. Vega...

Award-winning PDF software

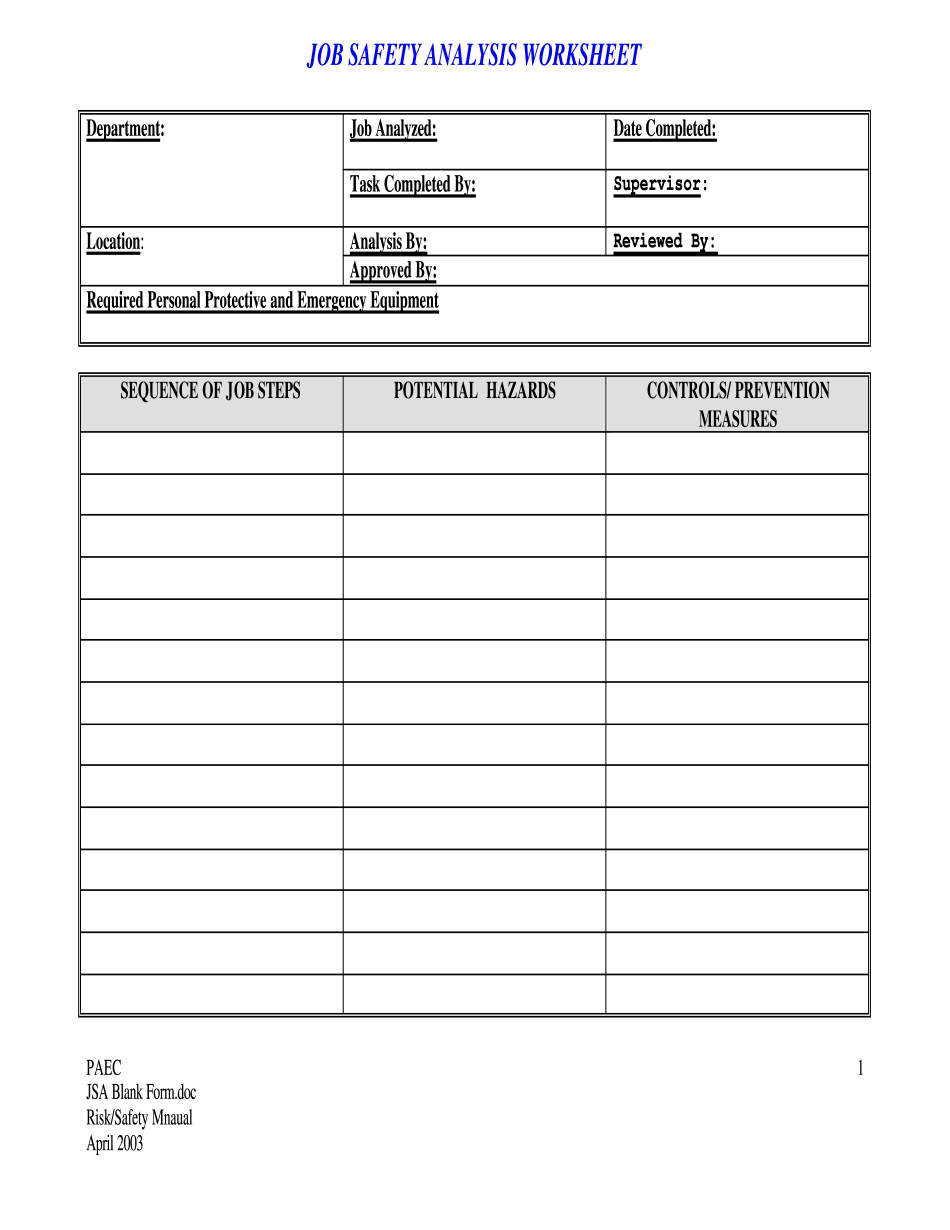

Jsa template wa Form: What You Should Know

The forms must be completed in person by a manager or supervisor in each Department to get approval. Petition/Application for Job Safety Analysis — Commerce WA JSA form for all employees to fill out and complete the job safety analysis form. Job Safety Analysis form in PDF format. Job Safety Analysis, fill out and complete the information online. JSA Template — Fill online, printable, fillable, blank — filler Forms to fill out and complete job safety analysis template. Instructions and suggestions on how to complete JSA form. JSA Risk Assessment Template | Job Safety Analysis Form Feb 28, 2025 — Learn more about the Formats JSA form for job safety analysis with hazards, controls & risk assessment matrix. Then try it out free on Android and iOS. New Application Requirements for Job Safety Analysis (JSA) — Commerce WA New Job Safety Analysis (JSA) Process for Job Safety Analysis — Job Safety Analysis form for all employees to fill out and complete the job safety analysis form. Required Training: No required training to complete the application. Job Safety Analysis Form in PDF format. JSA Form — Job Safety Analysis Process — Job Safety Analysis form for all employees to fill out and complete the job safety analysis form. Instructions and questions for Job Safety Analysis form in PDF. JSA Template — Fill Online, Printable, Fillable, Blank — fillable Download Job Safety Analysis Application Form PDF — jobsafetyanalysisform.pdf A complete application form which is used to complete Job Safety Analysis (JSA), which may include information such as location, organization, job requirements, and safety protocols. The form is filled-out by the employees involved during a mandatory review, which may be done at one of our designated Safety Training Centers or by our Safety Analysts. JSA form for all employees to fill out and complete the job safety analysis form. Job Safety Analysis form in PDF format. Job Safety Analysis, fill out and complete the information online. JSA Risk Assessment Template | Job Safety Analysis Form Jan 17, 2025 — Do you think we need another form? A form to fill out and complete the job safety analysis form? — no application required Job Safety Analysis (JSA) — Commerce WA Job Safety Analysis details. Work activity: Location: Who are involved in the activity: This job analysis has been authorized by:.

online solutions help you to manage your record administration along with raise the efficiency of the workflows. Stick to the fast guide to do PaEC JSa Form, steer clear of blunders along with furnish it in a timely manner:

How to complete any PaEC JSa Form online: - On the site with all the document, click on Begin immediately along with complete for the editor.

- Use your indications to submit established track record areas.

- Add your own info and speak to data.

- Make sure that you enter correct details and numbers throughout suitable areas.

- Very carefully confirm the content of the form as well as grammar along with punctuational.

- Navigate to Support area when you have questions or perhaps handle our assistance team.

- Place an electronic digital unique in your PaEC JSa Form by using Sign Device.

- After the form is fully gone, media Completed.

- Deliver the particular prepared document by way of electronic mail or facsimile, art print it out or perhaps reduce the gadget.

PDF editor permits you to help make changes to your PaEC JSa Form from the internet connected gadget, personalize it based on your requirements, indicator this in electronic format and also disperse differently.

Video instructions and help with filling out and completing Jsa template wa